Email:info01@cnoilmachine.com

Detailed palm oil refining process

Raw material pretreatment (1) Removal of impurities: Remove palm pulp, fruit shell and other impurities to obtain pure palm kernels. (2) Shelling: Peel off the shell of the palm nut to obtain the palm nut meat.

Breaking and Softening (1) Breaking: Break the palm nut flesh into small pieces. (2) Softening: By heating and adding water, the crushed palm nut meat is softened to a suitable level for pressing.

Oil extraction (1) Pressing: Press the softened palm nut meat through a press to extract oil. (2) Collection: Collect the squeezed oil.

Separation (1) Letting stand: Let the squeezed oil stand for a period of time to separate out impurities such as pomace. (2) Separation: Separate the oil and pomace through filters and other equipment to obtain pure palm oil.

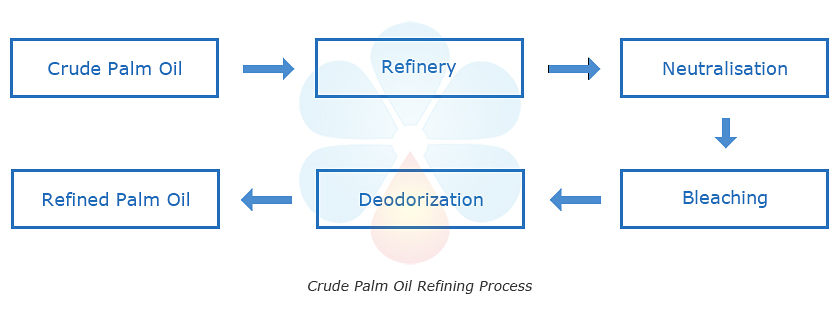

Neutralization: Adjust the acid value of palm oil to a suitable range and add an appropriate amount of alkali to neutralize it.

Bleaching: Remove pigments and other impurities in palm oil through adsorbents such as activated carbon.

Deodorization: Remove bad odors from palm oil through heating and vacuum deodorization.

Filtration: Filter the deodorized palm oil through a filter to remove fine impurities.

Filtration and packaging: Filtration: Filter the refined palm oil again through a filter to ensure the quality of the oil. Packaging: Filtered palm oil is filled and sealed for transportation and sale.

Henan Huatai Company has a professional and experienced team of engineers who can design a palm oil production line for you according to your needs and provide supporting palm oil plant design drawings. Choose Huatai and you will have a satisfactory palm oil factory design plan. any need please email to info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.