Email:info01@cnoilmachine.com

1-5 TPH Palm oil processing line is a complex process which includes palm fruit reception station, palm fruit sterilizing station, palm fruit threshing station, palm fruit digesting & pressing station and palm oil clarification station. Each palm fruit station works together can maximize the extraction of palm oil.

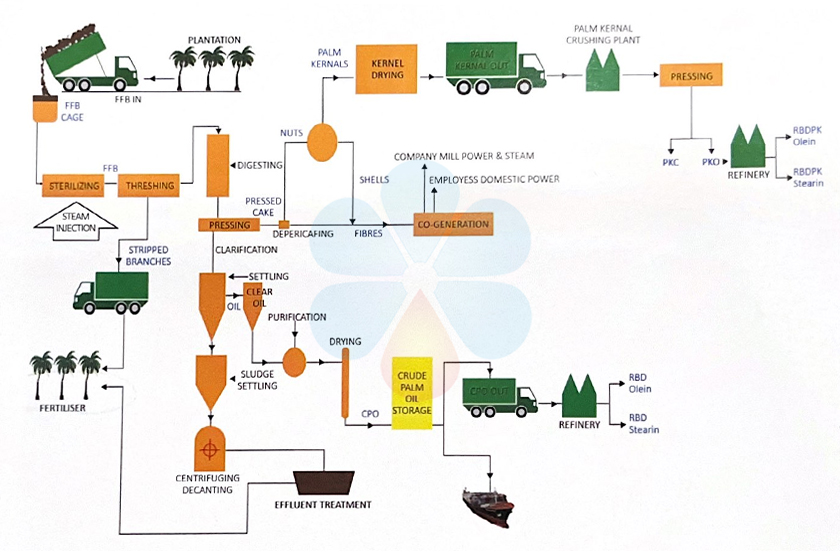

1. Palm fruit/bunch → sterilization → threshing → digesting → pressing→ clarification → purification →dring → CPO→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

2. Palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil, RBDPK olein & RBDPK stearin

Fresh Palm Fruit Reception: It is used for temporary storage and unloading fresh palm fruit bunches from palm plantation.

Palm Bunch Sterilization with the aid of steam: this loosens the oil-containing fruit from the bunch and inactivates lipid-degrading enzymes as well as micro-organisms that naturally occur in FFB.

Palm Fruit Threshing, bunch stripping which separates the fruit from the bunch stalk and spikelets. In this process, the byproduct Empty Fruit Bunch (EFB) is produced..

Palm Fruit Digestion to crush and disrupt the mesocarp (pulp), with the aid of steam.

Palm Fruit Oil Pressing of the digested fruit to extract the oil from the mesocarp fibre. In this process, two fractions are produced: raw oil and a residue, containing palm oil fibres and nuts.

Clarification and drying: The crude palm oil is separated from the mixture of oil, water and solid impurities by clarifying equipment, and other impurities are removed.

Crude Palm Oil Refining: The deacidified palm oil is refined, including bleaching, deodorization, dehydration and other processes to further improve the quality of the palm oil.

What are the main costs of palm oil processing line and production?

Palm oil processing line costs vary depending on region, scale, production technology, energy prices and other factors. Here are some factors that affect the cost of palm oil processing:

Labor costs: including labor costs in planting, picking, processing and other links.

Land rental or purchase cost: Palm oil cultivation requires occupying large areas of land, and land rental or purchase cost has a greater impact on palm oil processing costs.

Cost of pesticides and chemical fertilizers: In order to maintain the yield and quality of palm fruits, agricultural production materials such as pesticides and chemical fertilizers need to be used, which will also increase palm oil processing costs.

Energy price: Palm oil processing requires a large amount of electricity, steam and other energy, and changes in energy prices will directly affect palm oil processing costs.

Transportation costs: palm oil processing requires transportation from planting bases to processing plants, markets, and other places. Transportation costs are also one of the factors that affect palm oil processing costs.

Production scale: Large-scale palm oil processing mill can reduce the production cost of a unit product.

Production technology: The use of advanced production technology can improve palm oil production efficiency and product quality, thereby reducing palm oil processing costs.

In short, the cost of palm oil processing is determined by multiple factors, and the impact of each factor needs to be comprehensively considered for reasonable management and control.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.