Email:info01@cnoilmachine.com

Palm oil is derived from the oil palm tree originating from Africa. The highest concentration of palm oil fields is in Indonesia and Malaysia, which provide 85% of the world production; it is also cultivated in western Africa and South America. Since the 1990s, it has become a global commodity widely used in processed foods, in good part because of its high yield. A palm oil plantation yields between 1 (in Africa) and 3.8 tons (in Indonesia) of oil per hectare, compared to 0.8t for rapeseed, 0.7t for sunflower and 0.5t for soy.

Oil palm is a tropical plant species. It needs high rainfall, adequate solar radiation and high humidity to maximize photosynthetic capacity. The cultivation of oil palm is mostly done in a monoculture, except in Africa where it is part of an agroforest system. Palm trees are planted about 10 meters apart so that their crowns do not overlap. Three years after planting, the trees start to bear fruits, and reach peak production after about 10 years. After 25 years the trees become too tall, complicating harvesting, and yields decline; plantations are then cut down and new palms are replanted. Oil palm cultivation is labor-intensive because harvesting is largely manual. This high labor requirement makes oil palm an important livelihood option is many regions.

Fresh fruits are harvested about every two weeks and are crushed to extract the oil from the kernel and the flesh of the fruit, separately. The oil from the fruit goes into food production, whereas the oil from the kernel is used mostly for soap and industrial purposes, but also for processed foods.

After being harvested, the red fruit bunches(FFB) are delivered to the mills within 24 hours. Once there, these fresh fruit bunches(FFB) are divided into different groups to check their quality. The ripeness of the oil palm fruit is one of the most important factors that determines the quality of the bunches.

In the processing of fresh fruit bunches, palm oil mills produce palm oil mill effluent, empty fruit bunches, and finally, a mixture of kernel, fibers and oils. All of these elements eventually serve a purpose. But for palm oil, the fruit bunches are the most important element.

A next step in this journey is producing the oil. For this purpose, the fruit bunches are treated with steam. This is an important step as it eliminates any bacteria and puts a stop to enzyme activity. In this way, the degradation of the fruit is brought to an end.

In the meantime, the steamer softens the oil palm fruits, which in turn helps to relieve the natural oil. After this steam treatment, the fruit masses, which contain water, oil, fibers, palm kernel are treated to separate all components.

This natural fruit is then put under high pressure to squeeze out the oil and water. As a result, a water-oil mixture is produced. As water and oil do not mix after some time, the palm oil will form an oil layer on the top. In this way, the oil can be then extracted from the water. What it finally results are the first drops of natural crude palm oil. This will need further process at the refinery.

The kernel is transported to a palm kernel mill, which extracts the palm kernel oil. Such a mill is specially built to be able to crush the hard kernel. Palm kernel oil refinery plant featured advantages:

Palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. Palm kernel oil is non-drying oil with low gum content, which is suitable for physical refinery. Fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.

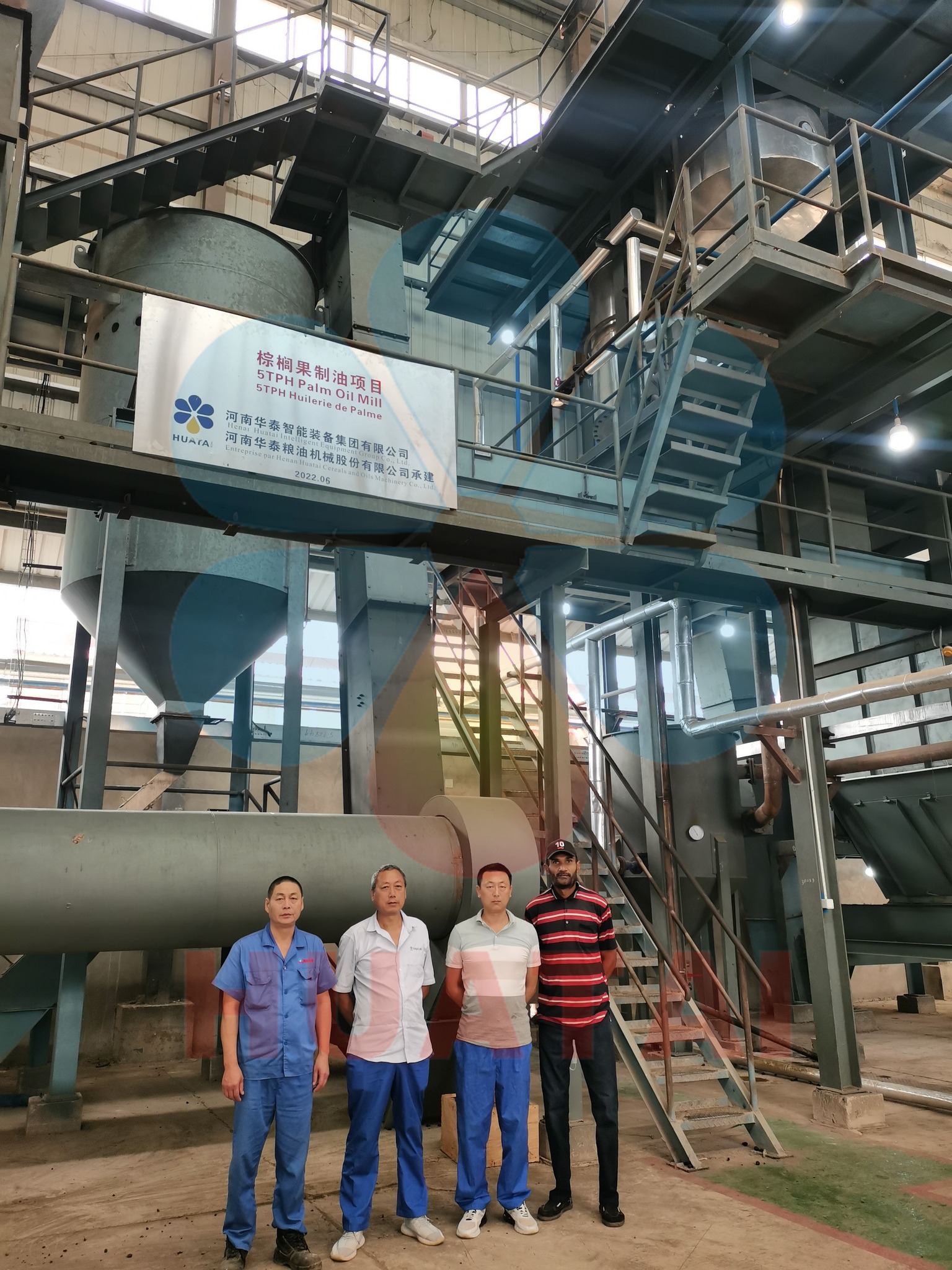

Henan Huatai Cereals and Oils Machinery Co., Ltd. specializes in manufacturing palm oil machinery, palm fruit oil extraction, palm kernel oil extraction, palm crude oil refining and fractionation.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.