Email:info01@cnoilmachine.com

The production capacity of the palm kernel production line: daily processing 200-100t/h, dry cake residual oil rate 8-13%, raw material: palm fruit kernels.

Palm kernel production line, palm kernel oil contains a large amount of lower fatty acids, so its properties are very different from palm oil, but very similar to coconut oil.

Palm kernel and fiber mixture → fiber and kernel separation → kernel shell separation → crushing → steaming and frying → pressing → filtering → palm kernel oil

1. Separation of fiber and kernels

If the raw material for palm kernel oil production is a mixture of palm kernel and fiber obtained after pressing palm fruit, then before pressing the palm kernel, the mixture must be processed with fiber and kernel separation equipment to separate the fiber and palm kernel, so that the palm kernel can be The oil pressing process proceeds smoothly, which improves the pressing efficiency and also avoids the impact of fiber clogging on the pressing process.

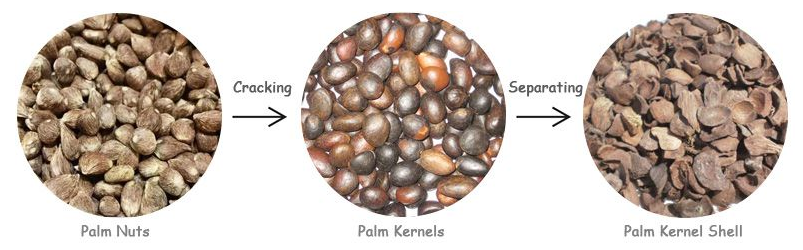

2. Kernel and shell separation

The palm kernel obtained after fiber separation also needs to be transported into the kernel shell separation system to separate the palm kernel and the shell. This will make it easier to squeeze out the palm kernel oil from the palm kernel and also avoid the impact of the palm kernel shell on the palm kernel oil pressing equipment. wear and tear to extend the service life of the equipment. If the raw material for palm kernel oil extraction is palm kernel without shell, it can be crushed directly.

3. broken

The purpose of crushing is to break the palm kernel into small pieces and increase the surface area of the palm kernel, which can improve the efficiency of palm kernel oil squeezing and extract more palm kernel oil. The equipment used in the crushing process is a crusher.

4. Steam and stir-fry

Steaming and frying is used to adjust the temperature, humidity and internal structure of the palm kernel so that it can reach a good state before pressing. The drum wok is a device used for steaming and stir-frying.

5. Press

Pressing is an important step in the production of palm kernel oil, which extracts palm kernel oil from palm kernels through mechanical extrusion. Due to the high hardness of palm kernel, there are some differences in structural design and equipment materials between palm kernel oil presses and ordinary oil presses.

6. Filter

The pressed palm kernel oil must first be filtered through a plate and frame filter to obtain clearer palm kernel oil, and the oil quality will be better.

All kinds of palm oil machine with different capacity, any need please email to info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.