China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

Palm oil is edible oil extracted from the fruit of oil palm. Oil palm is one of the four major woody oils. The oil content of the pulp is as high as 56% to 70%. The fatty acid composition of the extracted palm oil is mainly palmitic acid and oil. Acid, together with soybean oil and rapeseed oil, is known as the three major vegetable oils and has a history of consumption of more than 5,000 years. In recent years, the production and consumption of palm oil have continued to increase, which has prompted many customers to plan to invest in the construction of palm oil processing plants. However, if you want to build a factory to produce palm oil, you must first have an in-depth understanding of oils and fats before you can determine the direction of development. There are several reasons why palm oil is widely used. First, palm oil shows good oxidative stability when fried, so palm oil is often used in fried instant noodles, fried dough sticks, and French fries. Oxidative stability refers to the degree to which oil is oxidized during high-temperature frying. The oxidation of oil will affect the taste, flavor, color, and nutrition of the product, and can also easily produce substances that are harmful to the human body. After comparison, it can be found that when fried for a long time under the same environment, although the color of palm oil will deepen, the carbonyl value and polar compound content in the oil will be relatively reduced, and its strong oxidation stability is more suitable for frying.

In addition, palm oil, as a cooking oil, is the same as other edible oils. It can provide the human body with required fatty acids and other substances. In terms of vitamin E content, the content in palm oil is much higher than that of vegetable oils. In addition, palm oil It produces relatively few harmful components to the human body during continuous or repeated thermal processing, so it has a good advantage in the oil and fat market.

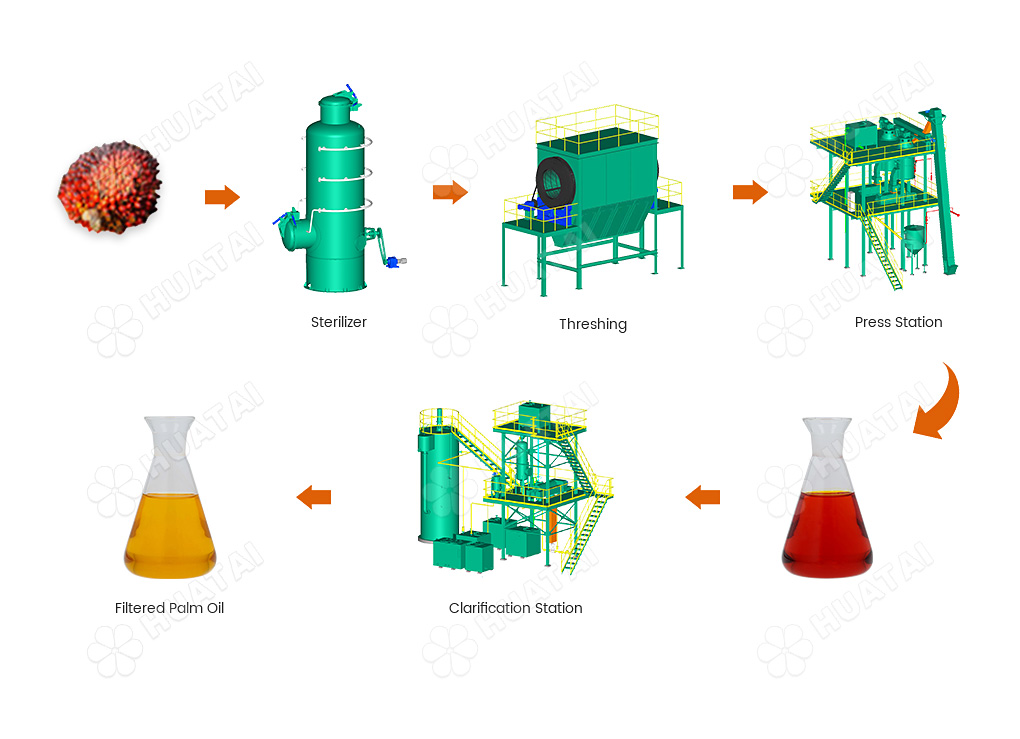

After understanding the market positioning of palm oil, investors must fully understand the processing process of palm oil, so as to facilitate the equipment of the oil plant to produce edible oil that meets market demand. Huatai Grain and Oil Machinery Equipment Manufacturer serves many palm oil plants. , here is a brief introduction for you that the transformation of palm fruit into palm oil requires a series of mechanized procedures, including sterilization, threshing, crushing, pressing, deacidification, decolorization, deodorization, fractionation, drying, packaging and other processes. Sterilization is an important step in palm oil processing. Mature oil palm pulp and kernels are rich in lipase, which can automatically degrade the fat in the fruit, resulting in an increase in free fatty acids, an increase in the acid value of the oil, and a decrease in quality. Sterilization is a heat treatment process that softens, loosens and detaches the fruit from the fruit stalk. It also reduces lipase activity to avoid producing a large amount of free fatty acids, thus ensuring the quality of the finished oil.

The fallen palm fruits need to be cleaned, screened, broken and other pre-processing processes to fully destroy the internal structure of the oil to achieve a state where the oil can be easily extracted, and then pressed or leached. Palm fruit has a high oil content, and the oil yield by mechanical pressing is in the range of 75% to 90%. In this process, oil mills can use screw oil presses for continuous processing to obtain a good oil yield. For most oilseeds, the pressed cake is leached during processing in order to reduce the oil content in the oil cake. In palm oil production, oil cake is usually rarely leached because the palm kernel and fiber are obtained after pressing the palm fruit. The mixture has very little residual oil in the cake, so there is no need to leaching the pressed cake to increase the oil yield, and the palm core can also be deeply processed to extract palm kernel oil, so the mechanical pressing method is basically sufficient to process palm oil.

The liquid obtained by pressing is a mixture of water, oil, dry matter, and fruit residue. Subsequent operations such as centrifugation and vacuum drying are required to separate other substances to obtain crude palm oil. Palm crude oil contains peptidic impurities such as phospholipids, proteins, and viscous substances, as well as impurities such as free fatty acids and pigments, which need to be separated through refining equipment to obtain healthy, nutritious and safe edible oils.

The refining of palm oil can be divided into two categories: physical refining and chemical refining. The main difference between the two processes is the separation method of free fatty acids. The deacidification process of physical refining is carried out simultaneously with the deodorization process. The deacidification process of chemical refining is usually It is placed after hydration and degumming. The physical refining deacidification method utilizes the highly volatile characteristics of free fatty acids and odor molecules under high temperature and high pressure conditions, and introduces steam into the crude oil to separate these impurities. There are strict standards for the content of phospholipids and pigments in oils during the physical refining and deacidification process. These impurities must be separated as much as possible during the degumming and decolorization processes to avoid reactions between peptidic impurities and pigments under high temperature conditions, affecting the quality of the finished oil. Chemical refining and deacidification is to add an appropriate amount of alkali solution to crude oil and use acid-base neutralization reaction to separate free fatty acids. It can also reduce the phospholipid content in the oil. Relatively speaking, the chemical refining process is relatively convenient to operate, but the wastewater generated needs to be treated to avoid impact on the environment.

Which refining process an oil factory chooses must be decided based on the actual situation. In this process, oil factories investing in and building palm oil plants cannot do without the application of mechanical equipment. It is recommended that oil factories cooperate with Huatai Cereals and Oil Machinery, which has rich experience and has served thousands of oil factories. Cooperate with equipment factories. The manufacturers have mature technical skills and serious and responsible staff, and can provide customers with reasonable mechanical equipment according to their actual conditions, provide oil plants with practical solutions, and assist oil plant production.We supply palm oil processing plant with competitive price, high pressing efficiency and good after sale service for palm oil production plant all over the world. Feel free to contact us to get the latest price of our palm oil plant, info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.