China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

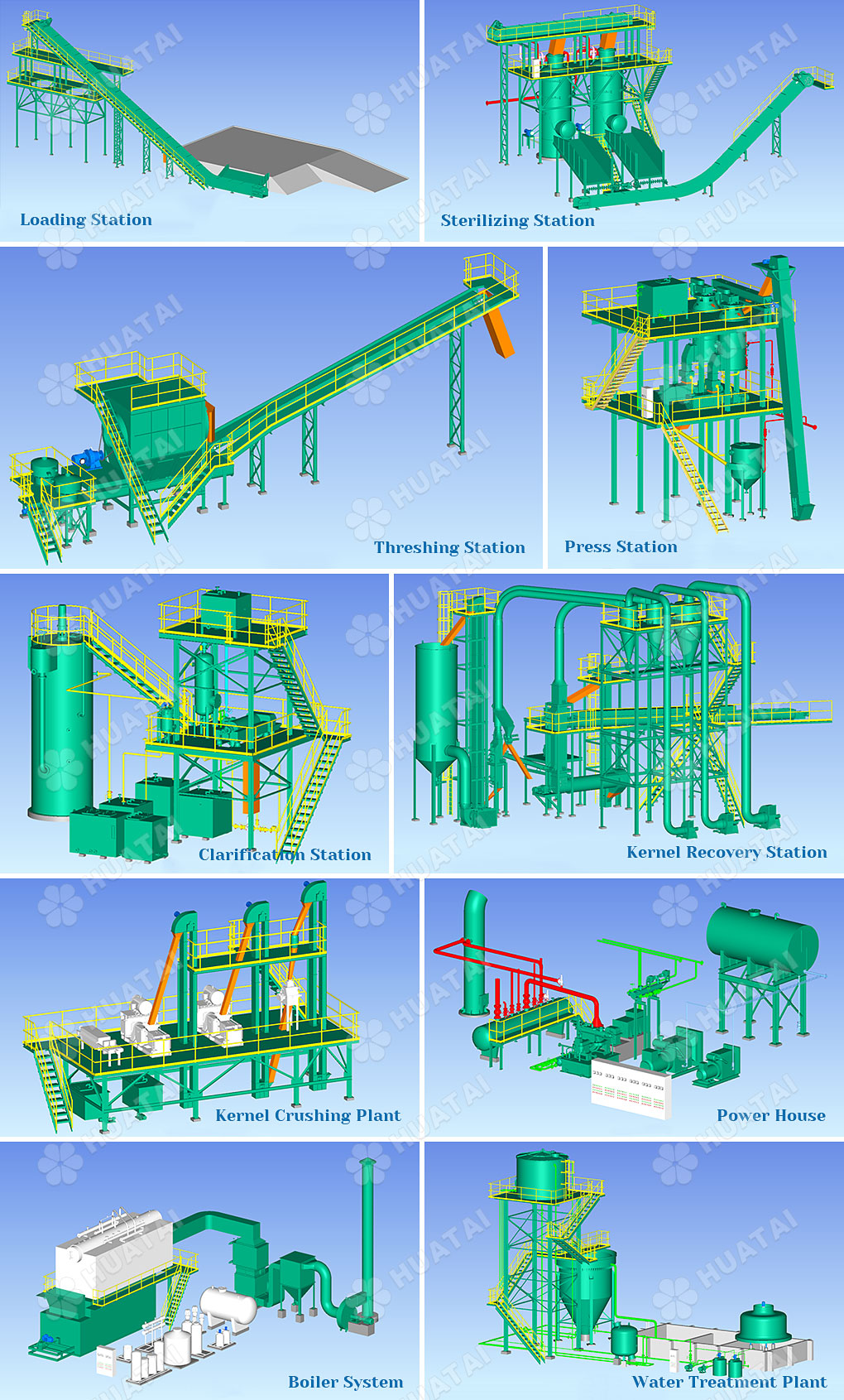

Palm Oil Processing Plant and Machinery

Loading ramp:

As palm fruit unloading, cleaning, storage platforms, all hydraulic segmented unloading.

Sterilization:

Cook the fruit bunches with high temperature and sterilization (145 ℃, 90-120minutes), easy to separate palm fruit from bunches, palm fruit becoming soft, increasing the humidity of the fruit, it is easy to extract the palm oil and also make the separation of the core-shell easier, preventing enzymatic decomposition to avoid free fatty acids content rising.

Threshing:

Through strong vibrations, the fruit will be separated from fruit bunches.

Palm Oil Pressing:

Separate the pulp and nut, get CPO and fiber cake, press machine adopts the double screw hydraulic continuous discharging, greatly improving production efficiency.

Clarification:

Separate the oil and the sludge (get 90% pure oil), the oil contains 45% -55% water, sludge and other things.

Purification:

oil purification process, improving pure oil

Drying:

Extract the water from the oil with continuous vacuum drier, the water can be reduced to 0.1%.

Depericarper (splitter):

Separate the fruit nut and fiber. Blow fiber and other lighter things outside.

Crushing (Crusher):

Crack the nut to get kernel and shell. In hydrocyclone, separate the kernel and core-shell according to their different proportion.

Henan Huatai Machinery is a palm oil equipment manufacturing company. We can provide turnkey palm oil refinery solutions such as palm oil plant layout design, machinery manufacturing, on-site installation and commissioning. Production capacity ranges from 2 ton/day to 500 tons/day.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.