Email:info01@cnoilmachine.com

Palm Oil Refinery equipment is the important palm oil machinery and equipment to ensure the quality, grade and safety of palm oil in the processing process. In the process of palm oil refinery. How to determine which process is used for palm oil refinery? The choice of palm oil refinery process can be follow the four principles.

Basing on the traditional Palm Oil Refinery technology, our company has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude palm oil of any quality. Moreover, a series of advanced technology and equipment are used, such as super wet degumming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, fractionation etc. Palm oil refinery is aim to remove phospholipids, FFA, pigment, gums, off-flavor and other impurities in the crude palm oil . The main process of palm oil refinery processes are: degumming & deacidification, bleaching and deodorization. After the primary stage of extraction, crude palm oil and crude palm kernel oil are sent to refineries for refining. After free fatty acids, natural pigments, and odors are removed, they become salad-grade oils-refined palm oil (RBD PO) and palm kernels Oil (RBD PKO).

The palm oil refinery process removes water, odouriferous matter, phosphatides, free fatty acids and other impurities including dirt and traces of metals from palm oil mill. After processed in palm oil refinery plant, the final oil product is a kind of premium edible oil of consistent quality which not only satisfies customer requirements and industry’s standards in respect of Iodine Value, FFA, flavor, color, melting point, peroxide value, impurities and moisture.

1. Degumming and Deacidification SectionPalm oil degumming and deacidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refinery process.

2. Bleaching Section in palm oil refineryPalm oil bleaching section is mainly used to remove oil pigment, residual soap and metal ions during palm oil milling process.

3. Deodorization Section in palm oil refineryPalm oil deodorization section composes of part of crude palm mill plant processing equipment. It plays important part in improving oil quality after crude palm oil process.

Palm Oil Refinery Plant

Palm Oil Refinery Plant

Palm Oil Refinery Plant

Palm Oil Refinery PlantIf you are planning to invest in a palm oil mill plant and have limited budget, some machines that can be replaced to save equipment cost. For detailed PKO project solution, you are welcome to contact us and tell us your needs. Our professional engineer team will help you make the best project solution and also offer the best price.We are committed to providing cost effective machinery and equipment which conform to the international quality standards, provides turnkey palm oil project including process design, palm oil machine manufacturing, installation, commissioning and training services. So far, Henan Huatai has successfully installed many palm oil mill plant projects in Africa.

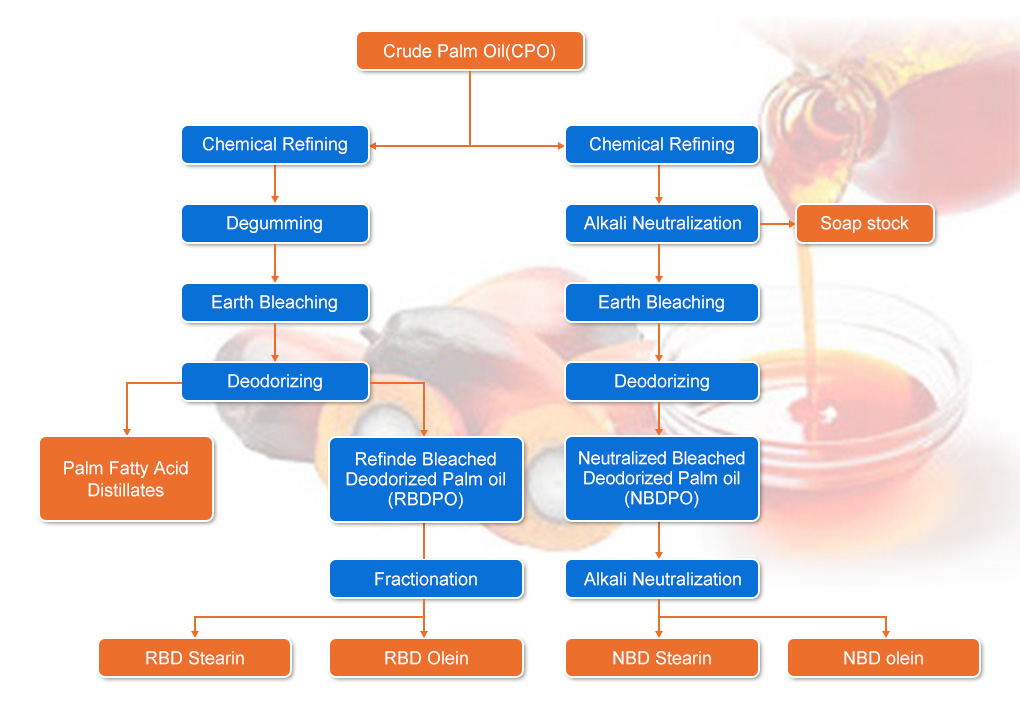

Crude palm oil can be processed by either physical refinery (distillative neutralization, steam stripping) or chemical refinery (alkaline refining) to produce RBDPO and NBDPO. RBDPO refers to refined, bleached and deodorized palm oil, while NBDPO refers to neutralised, bleached and deodorized palm oil.

Crude Palm Oil Refinery Process (Physical Vs Chemical)

As we all know, the palm oil fruit can yield two distinct edible oil - palm oil that is obtained from the outer part of the palm fruit and the palm kernel oil that is derived from the inter kernel of the palm fruit (palm nut). Physical palm oil refinery process is suitable for both crude palm oil and palm kernel oil.

The free fatty acids contained in it are removed using water vapor in the deodorization section. Has the following characteristics:

The oil refining rate is high and the loss is small;

Less production wastewater;

The amount of fatty acid distillate increases;

More suitable for oils with high acid value and low impurities.

High efficiency crude palm oil with low oil residual, palm oil refinery plant, strong brand, quality production, factory sales, no huge profits, timely delivery, safe transportation, patient answers, atperfect service, free training on equipment operation. We can provide turnkey palm oil refinery solutions such as palm oil mill plant layout design, machinery manufacturing, on-site installation and commissioning. Palm oil refinery production capacity ranges from 1 ton/day to 1000 tons/day.

After experimental studies, the oil yield of tons of crude palm oil is about 20%-23%. Of course, the oil yield is not fixed, it is affected by many factors, such as the ripeness of the palm fruit, the size and quality of the fruit, the method and time of harvesting, etc. Therefore, in actual operation, it must be adjusted according to the actual situation. The oil content of palm oil extracted from the fruit varies from 17% to 27%, while the kernel varies from 4% to 10%.

136 palm trees/Ha=20-23t FFB/Ha/year

CPO=4-5t/Ha/year

CPKO = 0.55 t/Ha/year

FFB=10-25Kg

FFB= 20% CPO; 2.5% CPKO

High Palm Oil Output Rate

High Palm Oil Output Rate| Project Name | Palm fruit skewers, containing about 65% palm fruit (of which about 52% palm pulp, about 13% palm kernel) |

|---|---|

| Oil Yield | about 26%, of which the residual oil rate is about 6% |

| Processing Capacity | 10 tons/hour, 8 hours per day |

| Power Consumption | 20kw/h |

The following is some onsite photos of our crude palm oil refinery projects. Feel free to contact us if you are interested!

Palm Oil Refinery

Palm Oil Refinery  Palm Oil Refinery

Palm Oil Refinery Palm Oil Refinery

Palm Oil Refinery Palm Oil Refinery in Ethiopia

Palm Oil Refinery in Ethiopia Palm Oil Refinery in Kenya

Palm Oil Refinery in Kenya Palm Oil Refinery in Uganda

Palm Oil Refinery in UgandaPalm oil refinery plant includes 3 steps: bleaching, deacidification and deodorization.

The only difference comes from capacity; In general, batch type palm oil refinery plant is utilized in palm oil refinery plant with capacity less than 20TPD; And semi-continuous palm oil refinery plant is suggested to capacity from 20-50TPD; finally continuous palm oil refinery plant is used for capacity above 50TPD.

Our engineer can help you deisgn whole palm oil refinery plant according to your capacity and requirements.

Huatai company offers complete small palm oil refinery and large palm oil refinery solutions. In addition, we also provide professional technical team to design the whole palm oil mill plant, help customers maximize the the commercial profits by making most use of the by-products produced during the process of palm oil mill manufacturing. We can provide a comprehensive and professional turnkey palm oil milling project.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.