Email:info01@cnoilmachine.com

Because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then sent it to continuous screw press.

Destroy the palm fruit pulp cell under the high temperature condition to make it easy to squeeze oil out. And then use mechanical pressing to get the crude oil out from palm fruit. The common used palm oil press machine is double screw palm oil expeller.

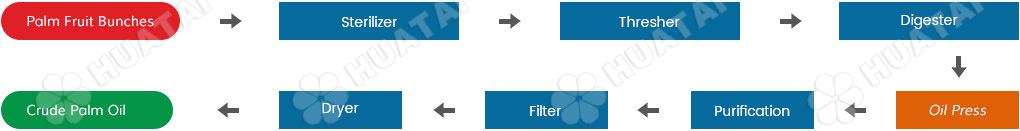

Process flow of palm oil processing line

Palm fruits through elevator and conveyors, enters into upper steaming boiler of palm oil press machine.

Stirring and heating with steam to destroy the emulsified state forming from oil and water, where in the coagulation protein denaturation and to reduce the viscosity of the oil for further convenience of palm oil pressing process.

Digesting temperature keeps at 95-100℃ about 20 minutes.

Palm fruit after digesting enters into screw oil expeller for palm oil pressing. Huatai patented palm fruit oil press has a processing capacity of 2-20TPH. This series of products is fully automatically controlled by PLC. The hydraulic system controls the cake discharging, which effectively reduces the residual oil in the cake and the core crushing rate. The spiral body and pressing cage are strong and have high service life long, the equipment operates stably.

After palm oil pressing, our machine divide oil palm fruit into two parts, the mixture of oil, water and solid impurities, and the press cake (fiber and nut). The pulp stone separation obtained CPO and stone, palm oil press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.