Email:info01@cnoilmachine.com

Huatai Company is a professional palm oil mill plant machine manufacturer. We can provide palm oil expeller machine, small scale palm oil mill plant, automatic palm oil mill plant, palm oil refinery machine and fractionation plant, turnkey palm oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. Our palm fruit oil processing plant capacity range from 3tph to 120tph. Welcome to contact us.

Final products: Crude Palm Oil (CPO) and Palm Nuts/Kernels

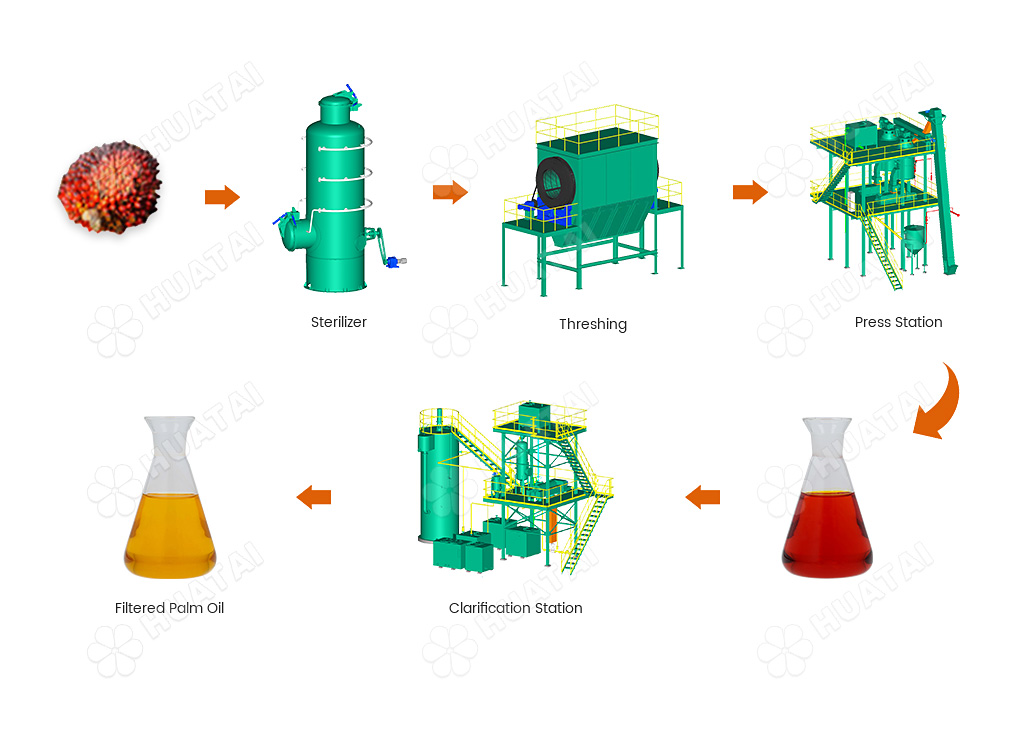

1. Sterilize in palm oil mill

As the first step in palm fruit crushing, sterilization is crucial to the quality of palm oil.

2. Threshing in palm oil mill

The main function of threshing is to separate the palm fruits from the fruit bunches. The sterilized palm fruit bunches are transported to the drum threshing machine.

3. Pressing Process in palm oil mill

The pressing process requires maximum extraction of palm oil from the pulp, but the kernels cannot be broken because the crushed palm kernel oil will contaminate the crude palm oil and affect the quality. Using two or more pressing processes can effectively reduce the cracking rate of nuts.

4. Purify And Clarify in palm oil mill

The mixture in the clarifier is crude palm oil, water and a small amount of solid particles. The traditional clarification method is gravity separation.

FFB Sterilization

FFB Sterilization

Crude Palm Oil Refinery

Crude Palm Oil RefineryIf you are planning to invest in a palm oil mill plant factory and have limited budget, some machines that can be replaced to save equipment cost. For detailed PKO mill plant solution, you are welcome to contact us and tell us your needs. Our professional engineer team will help you make the best palm oil mill plant solution and also offer the best price.We are committed to providing cost effective machinery and equipment which conform to the international quality standards, provides turnkey palm oil mill plant project including process design, palm oil mill machine manufacturing, installation, commissioning and training services. So far, Henan Huatai has successfully installed many palm oil mill plant projects in Africa.

After experimental studies, the oil yield of tons of crude palm oil is about 20%-23%. Of course, the oil yield is not fixed, it is affected by many factors, such as the ripeness of the palm fruit, the size and quality of the fruit, the method and time of harvesting, etc. Therefore, in actual operation, it must be adjusted according to the actual situation. The oil content of palm oil extracted from the fruit varies from 17% to 27%, while the kernel varies from 4% to 10%.

136 palm trees/Ha=20-23t FFB/Ha/year

CPO=4-5t/Ha/year

CPKO = 0.55 t/Ha/year

FFB=10-25Kg

FFB= 20% CPO; 2.5% CPKO

High Palm Oil Output Rate

High Palm Oil Output Rate| Project Name | Palm fruit skewers, containing about 65% palm fruit (of which about 52% palm pulp, about 13% palm kernel) |

|---|---|

| Oil Yield | about 26%, of which the residual oil rate is about 6% |

| Processing Capacity | 10 tons/hour, 8 hours per day |

| Power Consumption | 20kw/h |

If your palm fruit processing capacity is about 1-5 tons/hour, you can choose the standard configuration of palm oil mill plant line equipment, mainly by the fermentation tank, palm fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions, mostly suitable for medium-sized palm oil mill plants.

Investment in palm oil mill plants has a stable and broad market development prospects, mainly reflected in the palm oil processing raw materials sufficient, large market demand, and large profit margins.

The palm fruit tree is a long-term crop with four flowering and fruiting seasons. It can provide a stable and continuous supply of raw materials for palm fruit processing, and the yield per hectare of palm fruit is 5 times higher than that of peanuts in the same area, and 9 times higher than that of soybeans. People who have seen oil palm trees know that the fruit of oil palm trees is very rich, a large string, the fruit is orange red when ripe, and the average weight of each string can reach more than 100 pounds. In addition, the growth cycle of oil palm trees is perennial, blooming and bearing fruit all year round, and can harvest several times a year. And not only the fruit, the peel can also be used to press oil, so the oil yield per unit area of palm oil is also quite high. It requires very little to grow an oil palm tree, a tropical fruit tree that can survive in Asia, the Americas, and Africa. As long as the external environment meets its growth, it will seize resources and strive to grow at all costs.

At present, the palm oil imported from China is mainly used in the processing of composite edible oil, because of its low boiling point, many are used in the processing of instant noodles and biscuits. Palm oil also has many uses in the catering, food industry and oil and grease chemical industry. Palm oil is currently the world's largest vegetable oil production, consumption and international trade volume, accounting for 30% of the world's total oil consumption. This means that the market demand for palm oil is very high.

The net profit and rate of return on the production investment of palm oil mill plants are often the focus of our attention and one of the main criteria to measure the development prospects of palm oil mill plant projects. The net profit margin of palm oil is about 5% higher than that of soybean oil and peanut oil.

20TPH Palm Oil Mill Plant in Indonesia

20TPH Palm Oil Mill Plant in Indonesia 15TPH Palm Oil Mill Plant in Congo

15TPH Palm Oil Mill Plant in Congo 15TPH Palm Oil Mill Plant in Congo(DRC)

15TPH Palm Oil Mill Plant in Congo(DRC)Huatai Machinery is a China leading palm oil mill plant machine manufacturer and supplier, offering the factory price equipmnet and palm oil mill plant design at low cost, have set up multiple palm oil mill plant projects with customized production process in Africa. Palm oil mill plant process design is the design of the entire production process flow from palm fruit bunches to finished palm oil, designing the palm oil mill flow, we must ensure the advanced and scientific process.

Huatai Palm Oil Mill Plant Machine Offers Complete Palm Oil Mill Plant Solutions. In addition, we also provide professional technical team to design the whole palm oil mill plant, help customers maximize the the commercial profits by making most use of the by-products produced during the process of palm oil manufacturing. We can provide a comprehensive and professional turnkey palm oil mill plant project. Henan Hutai machinery have experienced engineers who can help customers design detailed palm oil production lines, provide installation services and guide the use of machines, truly achieve personalized services, and meet customers' all-round needs for palm oil processing. If you need any palm oil processing machines and palm kernel oil processing machine, palm oil refining machine please contact with us.

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.