Email:info01@cnoilmachine.com

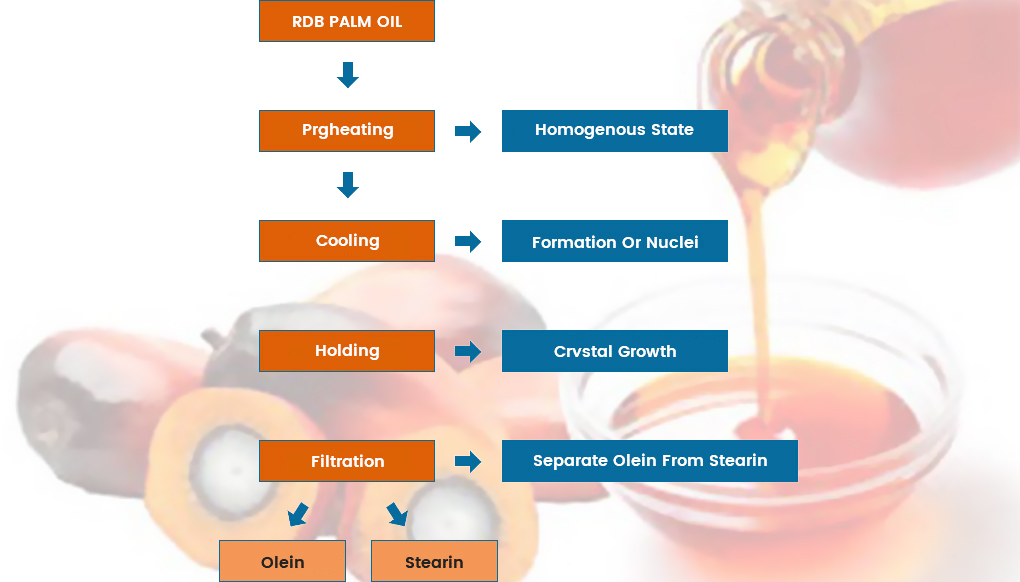

Palm oil fractionation equipment means that palm oil is divided into two parts by controlling the cooling and crystallization process of palm oil, low melting point liquid phase (soft fat) and high melting point solid phase (stearin). Due to different geographical locations, different countries have different temperature requirements for palm oil fractionation. There are three common palm oil fractionation temperatures: 18°C, 24°C and 36°C.

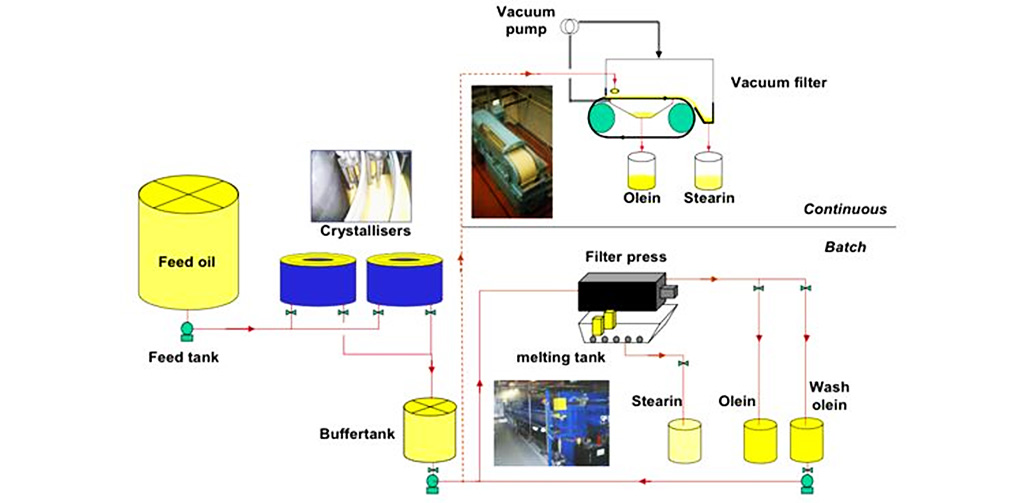

Dry fractionation technology, solvent fractionation technology and surfactant fractionation technology. Fractionation equipment adopts dry fractionation process. Dry fractionation is a relatively economical method.

Dry fractionation has the advantages of simple process, high degree of automatic control, low steam consumption, good product quality, no need for centrifugal separator, no other solvents, and no waste water.

Palm Oil Fractionation

Palm Oil Fractionation

Fractionation Workshop

Fractionation Workshop1. Heat Palm Oil Palm oil is semi-solid at room temperature and dissolves into a liquid state by heating with steam. Before crystallization, palm oil is usually heated to around 70°C to break up existing crystals.

2. Cooling And CrystallizationThe key to the palm oil dry fractionation process is cooling crystallization. If crystallization is successful, separation will be easy. Therefore, under the conditions of stirring and circulating water cooling, the cooling process should be controlled by setting the temperature difference between the oil and cooling water and the cooling time, so that it can form crystal nuclei and grow slowly. Cooling stops when the desired temperature is reached.

3. FilterIt is important to control the cooling and crystallization conditions, and the choice of filtration equipment also has a great influence on the yield of liquid oil. At present, the filtration systems used in industry are: drum filter, continuous belt vacuum filter and membrane filter.

Palm Oil Fractionation

As we all know, the palm oil fruit can yield two distinct edible oil - palm oi that is obtained from the outer part of the palm fruit and the palm kernel oil that is derived from the inter kernel of the palm fruit (palm nut). Physical refining process is suitable for both crude palm oil and palm kernel oil.

Tips: One time fractionation is enough in most cases. However, for some relatively high demand industry of stearin, confectionery industry for example, twice palm oil fractionation is suggested.

Palm Oil Fractionation Plant

Palm Oil Fractionation Plant Palm Oil Fractionation Plant

Palm Oil Fractionation Plant Palm Oil Fractionation Plant

Palm Oil Fractionation Plant Palm Oil Fractionation Plant

Palm Oil Fractionation PlantIf you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.