China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

What is the key factors to investing in a palm oil mill project:

1. Market research: Before deciding to invest in a palm oil factory, you first need to understand the needs, competition and development trends of the target market. Conduct in-depth market research to provide a strong basis for the construction of palm oil factories.

2. Site selection decision: Site selection is critical to the successful operation of a palm oil factory. Factors such as land cost, geographical location, transportation convenience, labor resources, and surrounding supporting facilities need to be taken into consideration.

3. Financing: Investing in building a palm oil mill requires a large amount of capital, so a suitable financing plan needs to be developed. Funds can be raised through self-raising, bank loans, seeking investment partners, etc.

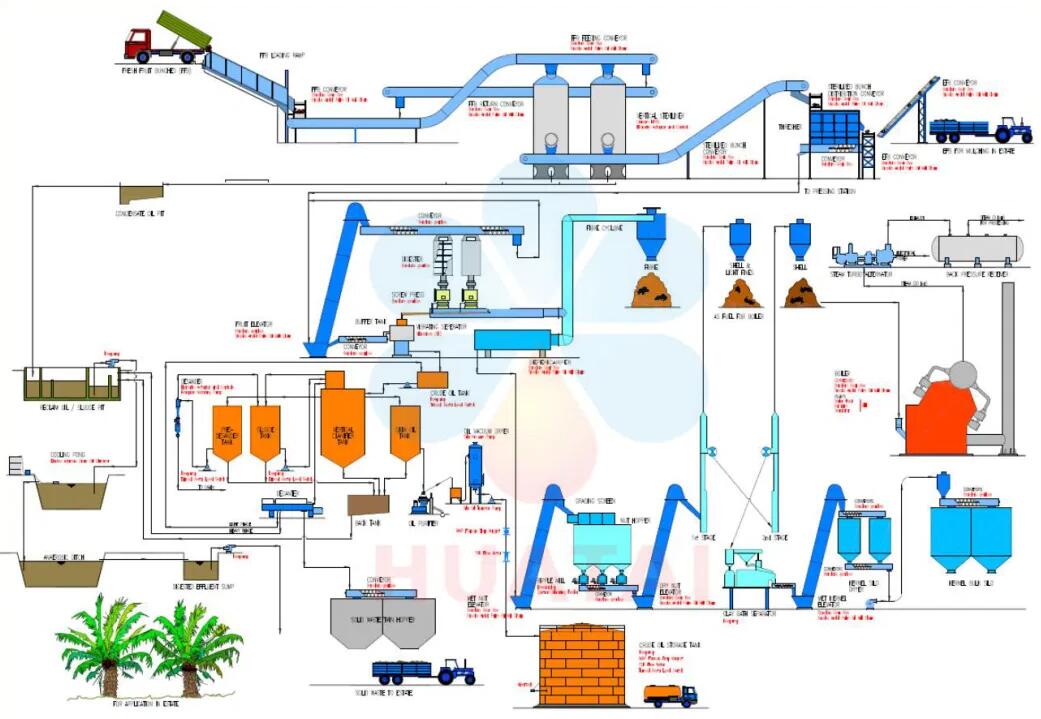

4. Palm oil factory design: Palm oil factory design needs to consider production process, equipment selection, process technology, safety and environmental protection, etc. A reasonable palm oil factory design can improve production efficiency, reduce costs, and improve the quality of palm oil products.

5. Palm oil equipment suppliers: Establish a stable supplier cooperation system to ensure stable supply of equipment quality and parts at reasonable prices. At the same time, factors such as supplier quality and delivery time should be taken into consideration.

6. Human resources management: Develop appropriate human resources plans, including recruitment, training, compensation and benefits, etc. An excellent team can bring higher production efficiency and product quality to palm oil factories.

7. Compliance with laws and regulations: Investing in and building a palm oil factory requires compliance with various laws and regulations, such as environmental regulations, safety production regulations, etc. Compliance operations can avoid unnecessary legal risks.

8. Risk management: Identify and evaluate the risks that may be faced during the investment and construction process, and formulate corresponding countermeasures. For example, policy risk, exchange rate risk, etc.

9. Palm oil equipment quality control: Establish a complete quality control system to ensure that product quality meets standard requirements. At the same time, we must pay attention to customer feedback and improve palm oil products and services in a timely manner.

10. Continuous improvement: Continuously pay attention to industry trends and technological developments, and continuously improve palm oil production processes and management processes. Improve the competitiveness of factories through technological innovation and management innovation.

Henan Huatai Company has a professional and experienced team of engineers who can design a palm oil pressing production line for you according to your needs and provide supporting palm oil plant design drawings. Choose Huatai and you will have a satisfactory palm oil factory design plan. Any need please email to info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.