Email:info01@cnoilmachine.com

Palm oil is the second largest edible vegetable oil in the world and plays an extremely important role in cooking and food manufacturing. However, crude palm oil contains many colloidal impurities, pigments and odorous substances that can affect its quality and safety. Some of these substances are harmful to people's health, and to ensure that it is suitable for consumption, crude palm oil undergoes a rigorous refining process.

The typical refining process for palm oil is physical refining.

The purpose of bleaching

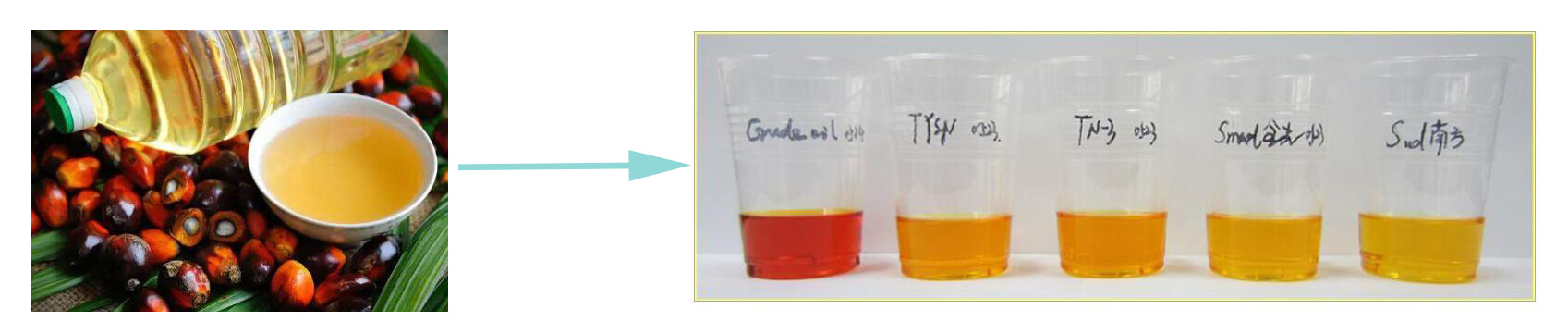

Removal of pigments: Palm oil contains pigments such as chlorophyll and carotenoids during processing or due to the raw material itself. These pigments can affect the appearance of palm oil, giving it a darker color that does not meet the color requirements of certain high-quality products or specific markets. Through decolorization, the color of palm oil can be lightened and its transparency and appearance quality can be improved.

Removal of impurities: During the decolorization process, some trace impurities in palm oil can also be removed, such as phospholipids, soapstock, oxidation products, metal ions, etc. These impurities may affect the stability and quality of palm oil. For example, phospholipids can cause the oil to precipitate during storage, while metal ions may accelerate the oxidation of the oil.

The main process flow is: crude palm oil → degumming → deacidification → bleaching → deodorization → refined palm oil. The purpose of palm oil refining is to remove various impurities in crude palm oil. After deodorization and removing impurities from crude palm oil, refined palm oil can be obtained.

Among them, decolorization is the most important link in the palm oil refining process and is also a key factor in determining the cost and quality of palm oil refining. Currently, the most effective method for palm oil decolorization is the joint use of activated carbon and activated clay to promote decolorization and purify the oil. Activated carbon can effectively remove macromolecular polycyclic aromatic hydrocarbons that clay cannot adsorb (while during the deodorization process, activated clay can only remove polycyclic aromatic hydrocarbons containing less than 4 low molecular weights). Activated carbon has a particularly strong adsorption effect on polycyclic aromatic hydrocarbons. Even if the activated carbon filter cake is pressed, the filtered oil does not contain polycyclic aromatic hydrocarbons.

The excellent adsorption properties of activated carbon ensure that even after filtration, the refined oil remains free of harmful PAHs. This dual approach using activated carbon and activated clay enhances the overall purification process of palm oil to meet strict consumer quality standards.

Henan Huatai Cereals and Oils Machinery CO.,Ltd supply complete palm oil processing machine, palm oil extraction, crude palm oil refining, palm oil refinery, fractionation, any need please email to info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.