China leading palm oil mill plant machine manufacturer and supplier

Email:info01@cnoilmachine.com

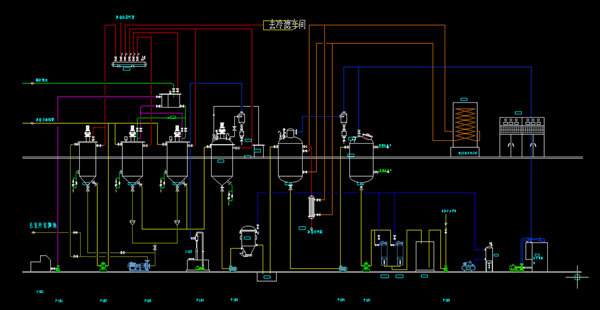

CPO Refining Process

The crude oil is pumped to refining pot from storage tank & it is treated with weak solution of suitable hot water and Phosphoric acid for removing gums. Refining pot are used to remove the FFA by adding alkali liquor. Oil is heated by heating coils and stirred. The chemical reaction forms the soap stock. It is later settled and collected after several hours. The oil is then washed to remove traces particles and free alkali.

Bleaching Section ( decolorization section)

Neutral oil is heated in the decolorization machine to remove excess moisture and color. It is also treated with measured quantity of earth. After several hours of controlled process, the oil passes through a filter media to separate the spent earth. Oil obtained after bleaching is light in color and has good appearance.

Deodorization section:

The deodorization process removes odor from the oil to improve the quality of oil. The clean bleached oil is heated in deodorizer pressure vessel to remove all the odiferous material such as phenols, ketones, tocopherols, aldehydes etc. The oil is heated at high temperature for several hours under vacuum and steam is allowed to release. Entire process is under high vacuum and high temperature.

For the refining part, we provide a full set of equipment for batch refining process, semi-continuous refining process, and full continuous refining process(more than 50 tons per day).

Batch refining process has a daily capacity of 1~30 tons of sunflower oil. It has features of less investment, convenient operation and small footprint.

Semi-continuous refining process has a daily capacity of 30~50 tons of seed oil. It can be used for different types of oil refining, and it has advantages of low power consumption, better refining rate than batch-type and traditional semi-continuous processes.

Full continuous refining process has a production capacity of more than 50 tons per day. With characteristics of high refining yield and low consumption of auxiliary materials, full continuous refining process can meet the requirements of deep processing of products. The process requires continuous operation, which is suitable for larger scale production of the continuous production enterprises.

Huatai professional palm oil refinery plant equipment, any need please email to info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.