Email:info01@cnoilmachine.com

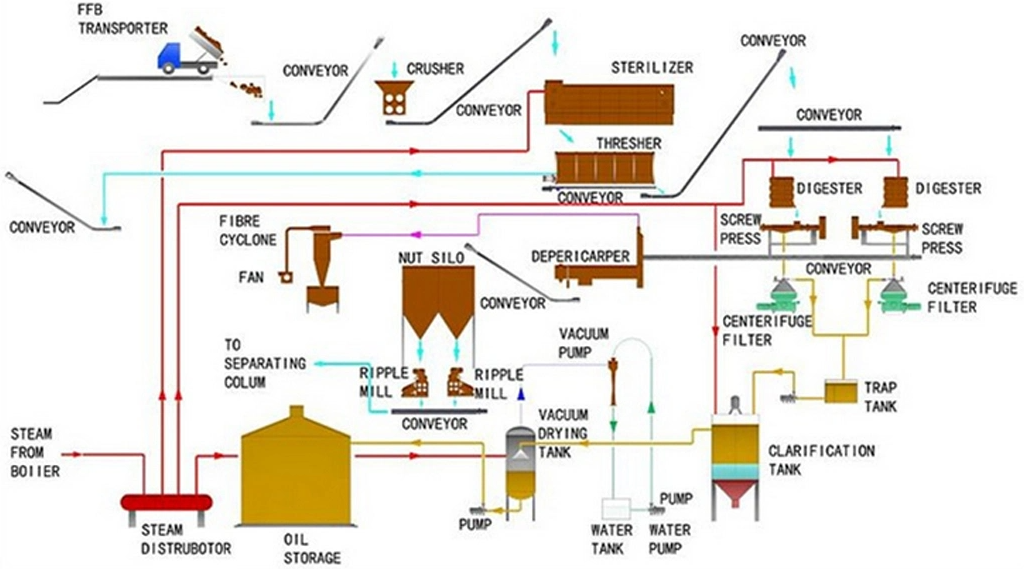

After transport the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm fruit cage. After separating palm fruits and palm bunch by thresher, Pam fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel. After pressing, we can get palm cake and palm nut. Pam nuts will be conveyed to palm recovery system to get palm kernels, fiber and palm shell. Palm cake will be conveyed to boiler room as fuel. After filtering, centrifuging, vacuum drying, we can get crude palm oi (CPO), the CPO can be sold directly or used for further processing. The sewage from all the plant will be processed by sewage treatment to reach discharge standard. Sludge can be used for fertilizer in palm plantation.

All the palm oil production process cycle features with short operation cycle, high automaticity, energy conservation and environmental protection.

Small palm oil mills need to be equipped with small palm oil pressing production lines. This production line mainly includes sterilization tanks, fruit threshing machines, crushing tanks, palm oil presses and plate and frame filters.

Henan Huatai Company has a professional and experienced team of engineers who can design a palm oil pressing production line for you according to your needs and provide supporting palm oil plant design drawings. Choose Huatai and you will have a satisfactory palm oil factory design plan.

any need please email to info01@cnoilmachine.com

If you are interested in our palm oil machine and palm oil mill plant. You can contact us through online consultation, filling out the form below, email, phone, etc. Our engineers will customize the most suitable plan and best price for you.